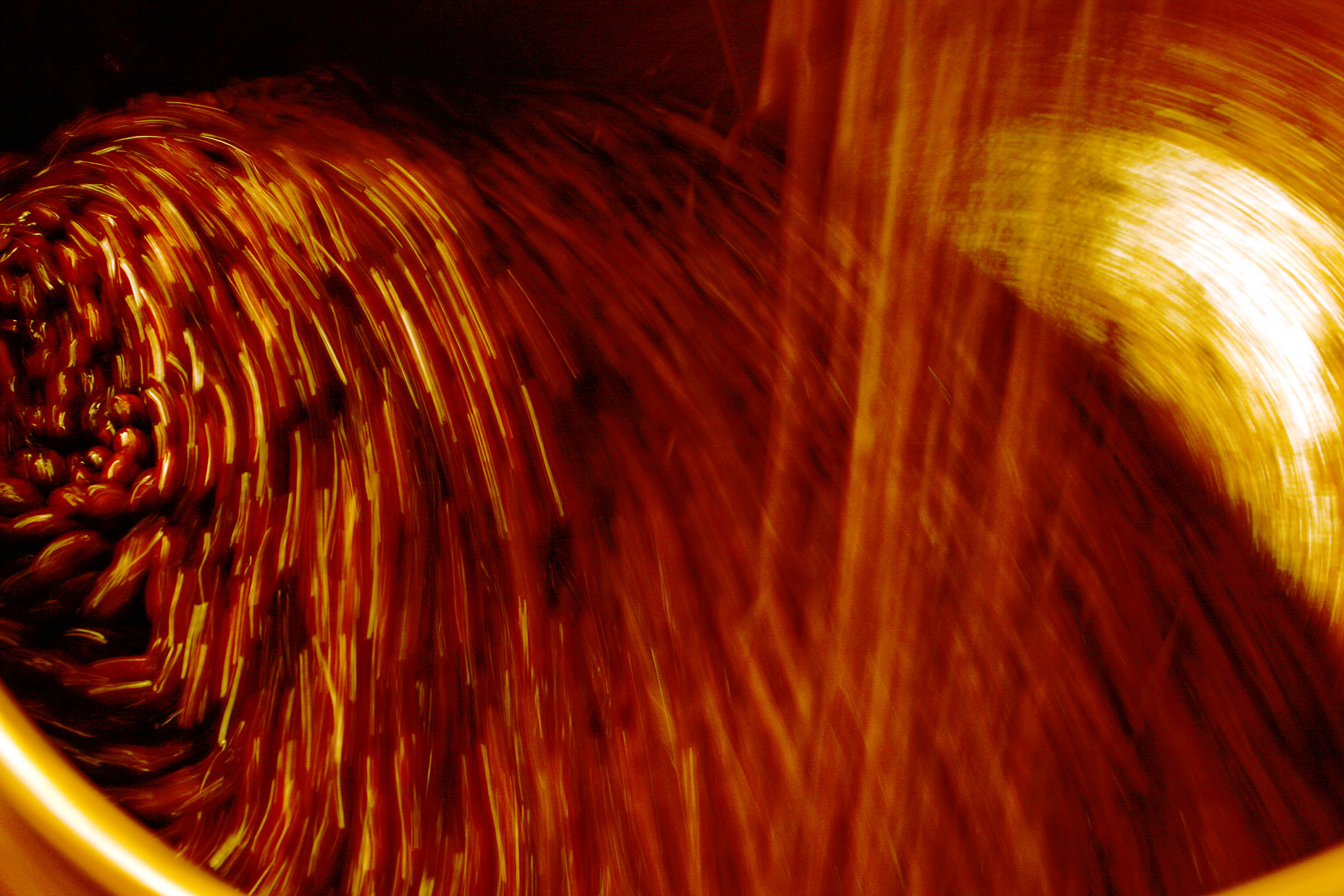

Tradition and manufacturing of a chocolate from another century

It was in April of 1954 when the master chocolatier, Francesc Agrás, embarked on a long journey through the best patisseries and confectioneries in Europe.

His passion for excellence in artisan confectionery was the seed that led to the founding of one of the most renowned Catalan chocolate factories: Bombons Blanxart.

It all started in a modest workshop in the neighbourhood of Les Corts (Barcelona) and feeding a dream:

Bringing the best cocoa beans from Ghana, Congo and Guayaquil to chocolate.